Features:

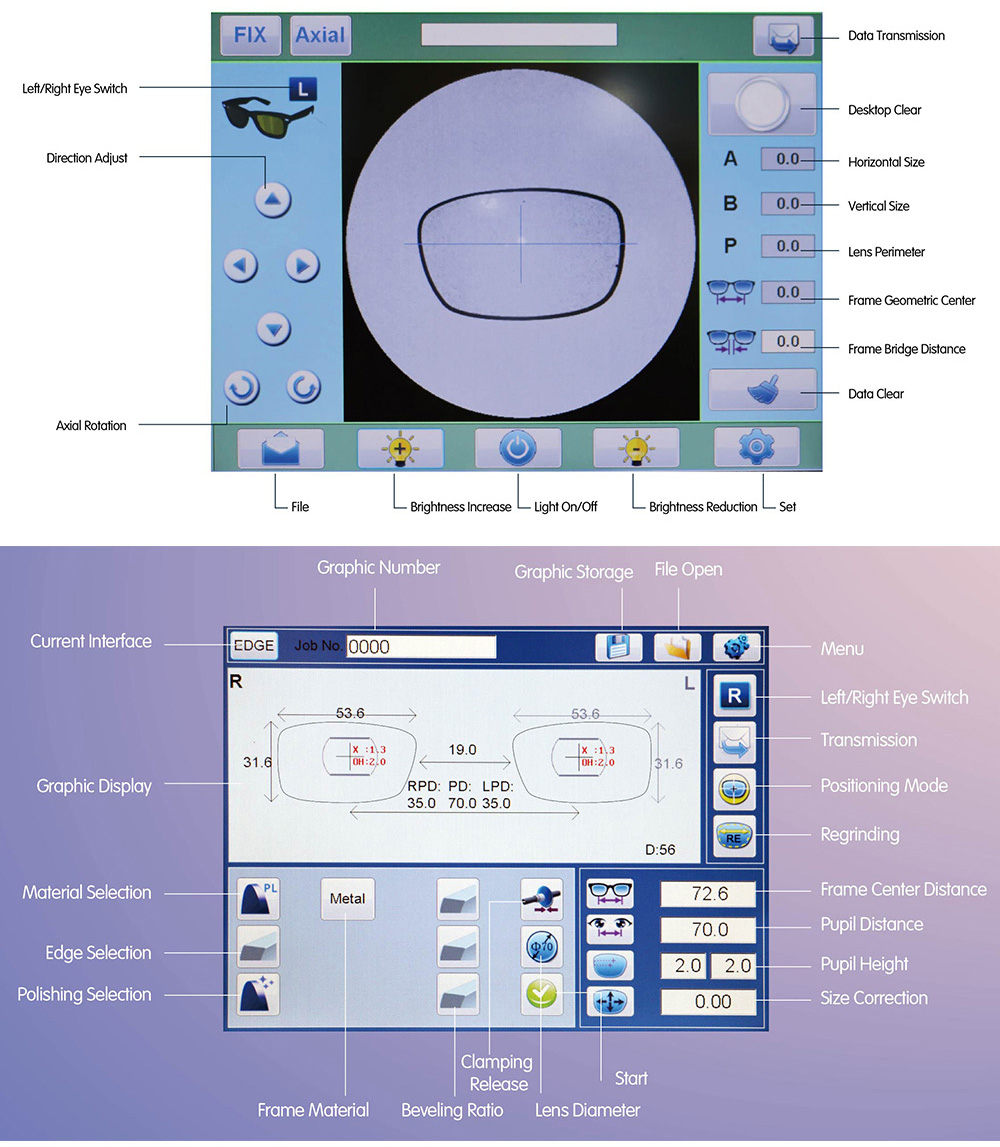

1. One-button operation, precise and fast scanning, accurate centering.

2. Super large touch screen, 1:1 ratio display, visual comparison betweenframe and scanned graphics.

3. Powerful and stable data processing, scanning graphics editable,multi-machines interconnection,

greatly high cost- effective.

4. Adaptive Clamp Chuck: Because of the large difference in thickness, the high curved lenses are

easy to cause displacement due to axis twisting during processing. The design of adaptive clamp

chuck ensures that the clamping force is balanced during processing to minimize axis twisting

and any potential damages to lenses.

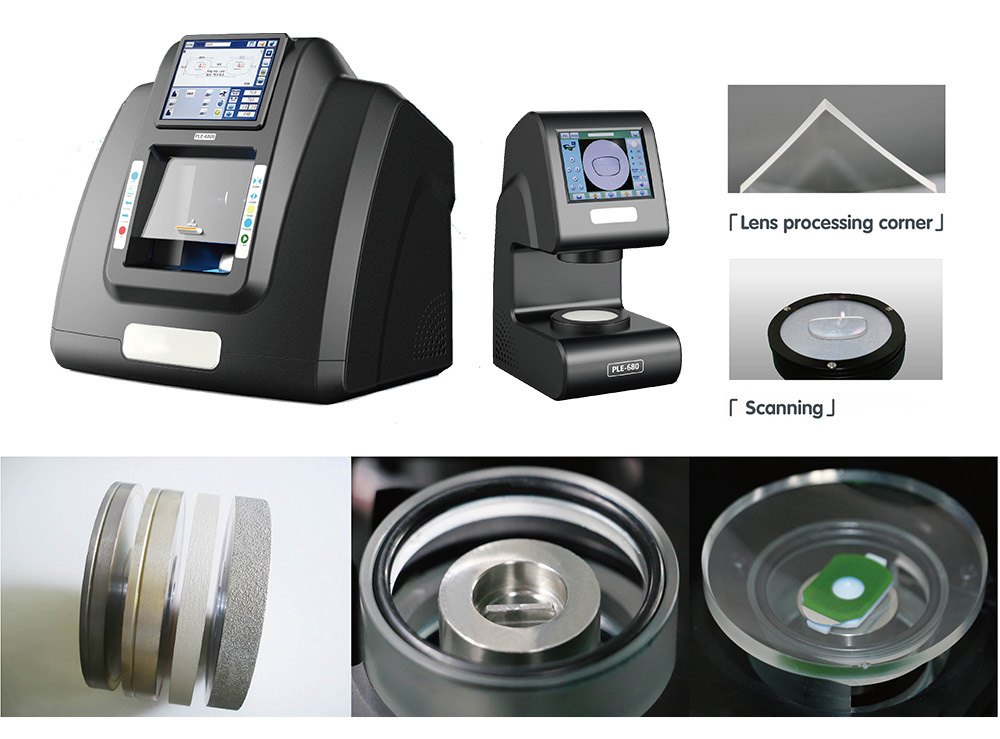

5. Bidirectional Curve Scanning Feelers: Precise scanning and positioning of the front and back

curve of lenses to ensure the accuracy of lens edging shape.

European Diamond Wheels Group: Perfect edging, high fineness, durable for long use.

Technical Data:

| PL-6800 Edger : | |

| Graphic editable and scalable functions | |

| Bidirectional water jet and built-in lighting in processing cabin | |

| Adjustable beveling position | |

| Max. number of stored images | 400 pcs |

| Lens Material | Plastic, Polycarbonate, High index plastic, Glass, Trivex |

| Diameter of diamond wheels group | 100 mm |

| Edging Mode | Beveling(normal/auto/manual mode), Flat edging, Polishing |

| Max. Cutting Diameter | 80 mm |

| Mini. Beveling Size | 22 mm |

| Mini. Flat Edging Size | 20 mm |

| Max. Frame Center Distance | 100 mm |

| Display | 10.4 inch color TFT LCD touch screen with angle adjustable |

| Input Voltage | AC 220V, 50Hz / AC 110V, 60Hz |

| Output Voltage | DC 5V 3A; DC 24V 5.8A |

| Power Consumption | 1000W |

| N.Weight | 48 kg |

| Dimensions | 636 mm x 452 mm x 591 mm |

| PL-680 Scanner/Blocker | |

| lmaging System | Dual center optical imaging system |

| Scanning and Positioning System | Scanning imaging, precise center positioning |

| Scanning Time | < 3 s |

| Scanning Precision | 0.1 mm |

| Display | 8 inch color TFT LCD touch screen |

| Power Supply | AC 100-240V, 50/60Hz |

| N.Weight | 9 kg |

| Dimensions | 470 mm x 230 mm x 320 mm |